In the US, 1,558 military personnel lost a limb due to the wars in Afghanistan and Iraq. Shockingly Ukraine is facing a future with between 20,000 and 50,000 amputees, according to military personnel human rights organisation Pryncyp.

Yet prosthetics are traditionally costly, uncomfortable to wear, require lengthy rehabilitation and in the case of growing children, frequent replacements.

But I recently met one Ukrainian startup determined to change this, while attending the IT Arena conference in Ukraine.

SYLA is developing an AI-enhanced bionic prosthetic knee that utilises advanced algorithms to adjust the user's walking pace dynamically, ensuring a seamless transition from slow walks to brisk runs.

And the company didn’t just impress me, it won a special prize of $10,000 for the most impactful startup from ЗMIN Foundation at the Lviv-based event.

SYLA is the brainchild of Mykola Lozinskyi, and Ilias Abliakimov, CTO.

Lozinskyi, has a background in product design engineering from his roles at Yandex and Meta. He also co-founded design studio Running Guy and founded WOYS.TOYS. Ilias Abliakimov held previous roles at DroneUA and Nokia.

I spoke to Lozinskyi to learn more.

SYLA tackles the high cost and limited adaptability of prosthetics

The idea for the SYLA spun out Lozinskyi’s time at Sevastopol State Technical University working in a biometrics laboratory where he gained an understanding of the mechanics of walking.

The 12-person company has staff in Boston, Warsaw and Kyiv: most with an engineering background in either electrical, mechanical, or software engineers who met while studying biomechanical robotics at university. It started developing prototypes in 2023.

Lozinskyi, shared:

“We believe everyone deserves the freedom of movement, and we're committed to overcoming the limitations of even the most expensive bionic knees.”

According to Lozinskyi, in Ukraine “some of the biggest challenges begin with proving that a prosthetic leg is a medical necessity.”

Further, prosthetics are prohibitively expensive, costing around $50,000 in Ukraine and as high as $100,000 in the US — worse they need to be changed every three years.

“Traditional prosthetic lower limbs often struggle to adapt in real-time to changes in a user's behaviour, such as transitioning from walking to running.”

SYLA is working on a prosthetic knee with a building cost of materials of just $5,000, with superior mobility.

The SYLA X1, an adaptive microprocessor knee, empowers above-knee amputees, supporting up to 100 kg of body weight, ensuring durability and stability.

Existing bionic knees require manual pre-selection of activity modes (like running or walking) via a mobile app,

Lozinskyi shared:

“Most prosthetic legs rely on hydraulic systems, which offer limited adaptability.”

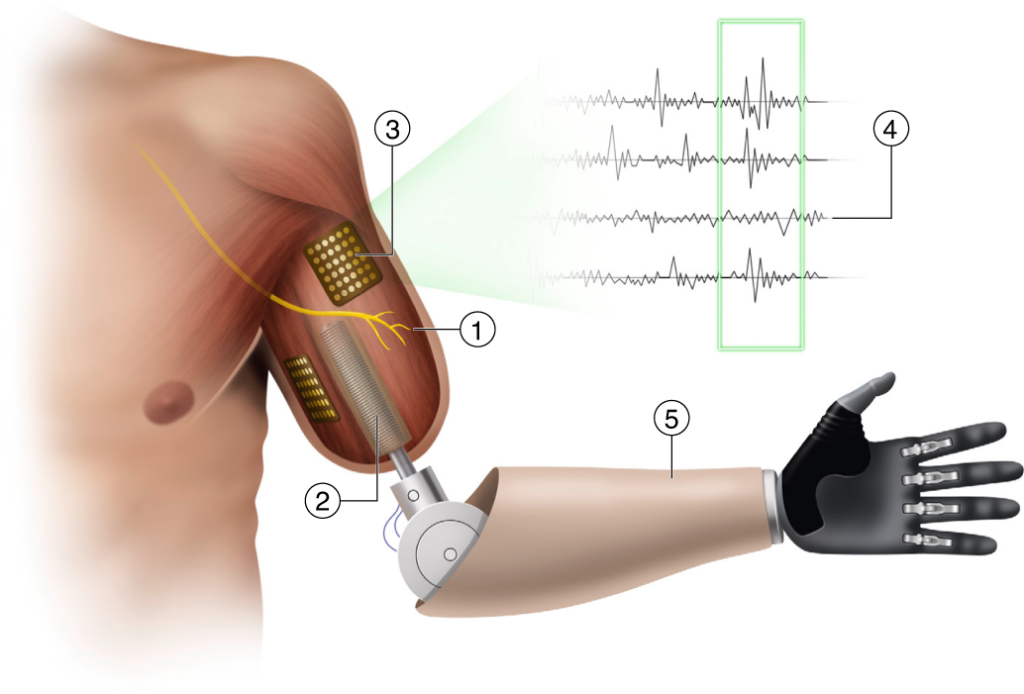

Unlike traditional hydraulic systems, SYLA X1 leverages electric motors, microelectronics, and advanced signal processing to offer more dynamic and responsive movement.

Unlike bionic knees with hydraulic units, the SYLA bionic knee uses a built-in motor.

The prosthetic knee incorporates advanced sensor technology including Inertial Measurement Units (IMU) and load cells that continuously monitor the user's movements.

These sensors facilitate a dynamic response system, adjusting in real-time to changes in terrain and walking speed, ensuring stability and fluidity in movement. Integrating machine learning algorithms allows the knee to learn from the user's walking habits, enhancing its functionality over time.

Sensors detect the speed and various positioning of the leg and a corresponding machine-learning model can predict the next movement.

The bionic knee’s dynamic response system operates without needing an app and the prosthetic supports up to 100 kg of body weight, ensuring durability and stability.

Modular design and plans for regenerative features

As a modular component, the bionic knee can be easily installed as part of a complete prosthetic leg by prosthetists in clinical settings, enabling precise adjustments to maximise patient comfort.

Battery life varies based on daily usage and most users can expect an average of 5,000 steps per charge if walking at speeds up to 10 km/h. Battery life will be shorter during running activities.

SYLA also plans to implement battery recuperation - much like regenerative batteries in ebikes where pedalling helps charge the battery.

Importantly, the prosthetic is also equipped with a polycentric mechanism, which allows it to be used to walk without power from the battery—albeit briefly—when it has run flat.

Lozinskyi explained:

“You cannot run on it, but you can slowly get back home.”

SYLA's agile approach to hardware development

Lozinskyi’s background launching products for millions of devices and 10 years of experience in hardware development has enabled him to understand the full life cycle from R&D to mass production.

He notes:

“The most tricky thing in developing hardware is testing out different iterations and determining market readiness.

Because with consumer electronics, you can go to the market with the first full version of the device, and it works but without full functionality.”

Lozinskyi explained that “Post-launch, we plan to continually enhance the prosthetic knee's capabilities through software updates that will introduce additional movement patterns tailored to diverse activities such as hiking, cycling, skiing, boxing, etc.

“Each update aims not only to expand the knee’s versatility but also to include personalised motion patterns for individual users, catering specifically to their lifestyles and needs.”

Running Guy and SYLA collaborate on textile-dressed prostheses

In Ukraine and globally, there’s a growing demand among amputees for self-expression, with many wanting to display their prosthetic limbs confidently rather than feel awkward about limb loss.

SYLA is using textiles by Running Guy Studio to make the prosthetic device less noticeable, thus enhancing amputee’s comfort and confidence.

SYLA preparing the knee for MVP testing with patients around Q1 2025.

The MVP knee will use definitive materials and components designed to withstand critical loads. The testing goals include ensuring that patients can stand, walk at varying speeds, and run on the knee. During testing, the team w’ll collect data to further train the model. Testing protocols are being developed with guidance from clinics and gait labs to optimise accuracy and safety.