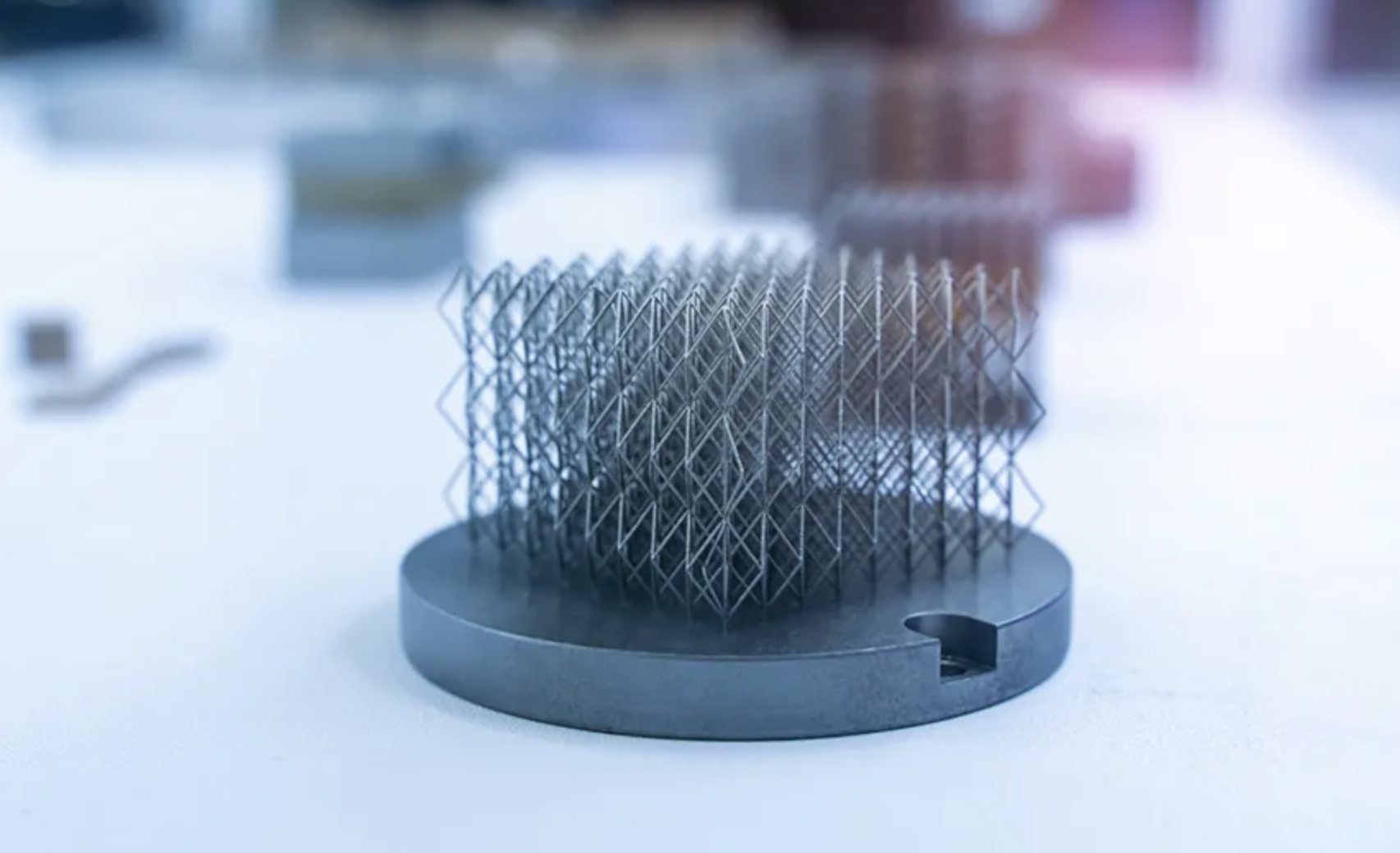

Qwadra, the digital division of Eqwal and a global provider of digital solutions in the orthotics and prosthetics (O&P) sector, has formed a strategic partnership with Denmark-based Create it REAL, known for its advanced 3D printing technologies. The collaboration involves incorporating Create it REAL’s multi-patented Programmable Foam technology into Qwadra’s Sona Flex and Sona Edge 3D printers. This integration is expected to enable healthcare professionals to produce custom orthopedic devices with greater precision, speed, and material efficiency.

The Sona Edge printer is designed to manage varying zones of rigidity and flexibility within orthopedic corsets, allowing for a more personalized fit. By utilizing Programmable Foam technology, clinicians can tailor devices to meet specific patient needs, potentially improving therapeutic outcomes. Luc Boronat, CEO of Qwadra, stated, “This partnership with Create it REAL reinforces our position as a leader in 3D printing innovation for the orthotics sector. The ability to manage rigidity and density in Sona Edge and Sona Flex allows practitioners to produce custom orthopedic devices that maximize both comfort and therapeutic effectiveness while reducing waste.”

Create it REAL’s CEO, Jacob Nissen, highlighted the environmental benefits: “We are on a digitalization journey with a higher goal of making the future greener. The partnership with Qwadra is a major step in integrating CAD systems with advanced 3D printing technologies, enabling sustainable production and reduction of the carbon footprint in the healthcare industry.”

Beyond improving patient comfort, the partnership focuses on responsible resource use. The new production methods aim to reduce material waste significantly and support recycling initiatives, contributing to a more circular economy. The Sona Flex printer allows practitioners to manage a wide range of foam densities, providing a balance between orthopedic correction and patient comfort. Both platforms are set to evolve in the coming months, offering expanded capabilities for designing and producing orthopedic devices.