The United States Patent and Trademark Office (USPTO) has granted Nike‘s patent for a new footwear 3D printing process.

In the global fashion brand’s novel method, digital designs are 3D printed onto fabric material to create the shoe’s upper. The sole is then 3D printed directly onto this section, eliminating the need for traditional two-part shoe construction techniques.

Nike’s approach offers advanced material customization, allowing designers to enhance strength, rigidity, support, flexibility, and abrasion resistance. Removing heavy adhesives, stitching, and excess material layers could also enable lighter footwear designs. Additionally, the newly granted patent (US-12226973-B2) has the potential to reduce material waste, making custom products more sustainable.

David P. Jones and Ryan R. Larson are the key investors named in the patent, which was first filed in December 2023 and published last April before being granted this week. Jones is a co-inventor on several patents related to 3D printing directly onto fabric for apparel assembly. Larson, Director of Nike’s Digital & 3D Cushioning Systems for Footwear Cushioning Innovations, is also an active figure in the company’s additive manufacturing efforts.

Over a decade of 3D printed footwear innovation at Nike

Additive manufacturing is nothing new at Nike. Back in 2013, the Oregon-based shoe-making giant unveiled its first 3D printed football boot, the Vapor Laser Talon. SLS additive manufacturing was used to produce the cleat’s footplate, reportedly cutting the weight to 158 grams for faster sprinting and optimal traction.

Several announcements followed, including a 2016 partnership to leverage HP’s Multi Jet Fusion (MJF) 3D printing technology. That same year, Nike introduced Zoom Superfly Flyknit running shoes, designed for 7-time Olympic gold medal-winning sprinter Allyson Felix. Spike plate prototypes were 3D printed in SLS to determine the perfect ratio of flexibility to bounce. This reportedly reduced iteration times to days, accelerating the design process. Legendary Jamaican Women’s 100m sprinter Shelly-Ann Fraser-Pryce also collaborated with Nike to prototype custom 3D printed footwear for the 2016 Olympic Games.

The world-leading shoemaker continued its 3D printing-enabled athlete collaborations in 2018, when former men’s marathon world-record holder Eliud Kipchoge adopted Nike shoes with a fully 3D printed upper section.

The Vaporfly Elite “Flyprint” shoes marked a distinct move away from the company’s use of additive manufacturing, shifting from prototyping to production. At the time, Nike’s senior director for global running footwear, Bret Schoolmeester, told Wired, “This is the first [3D printed] upper that will be more mass applicable.” Later that year, Nike extended the release of these athlete-grade running shoes into the wider market.

More recently, Nike made headlines last year with the launch of Air Max 1000, its first sneaker produced almost entirely with 3D printing. Unveiled at ComplexCon in Las Vegas, the new design was developed with Berlin-based Zellerfeld, a company known for its 3D printed footwear expertise. 1,000 pairs were made available through a raffle preorder at the Vegas-based fashion and music event.

Nike’s new footwear 3D printing patent

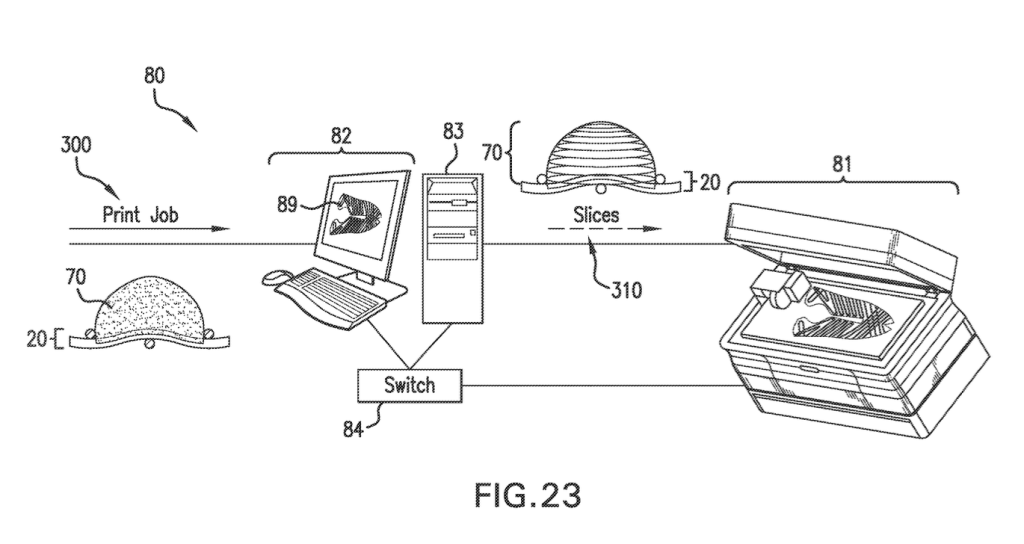

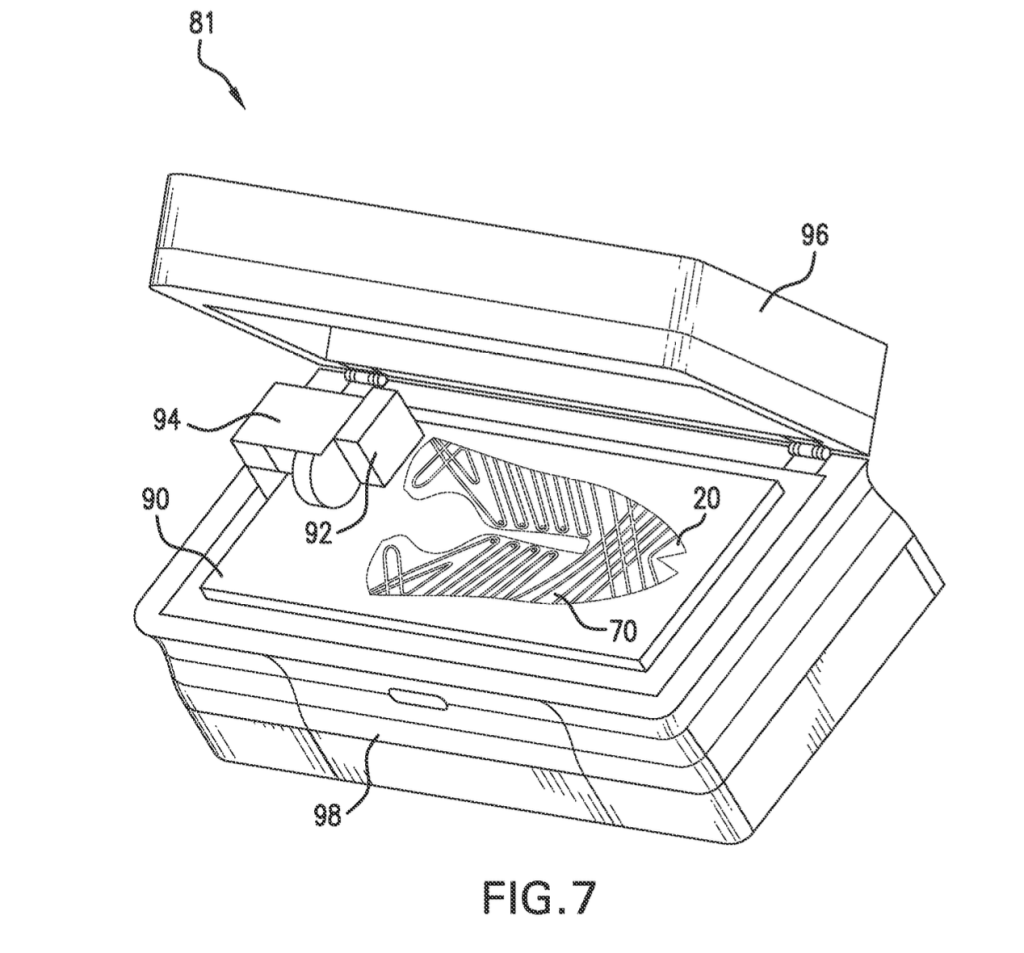

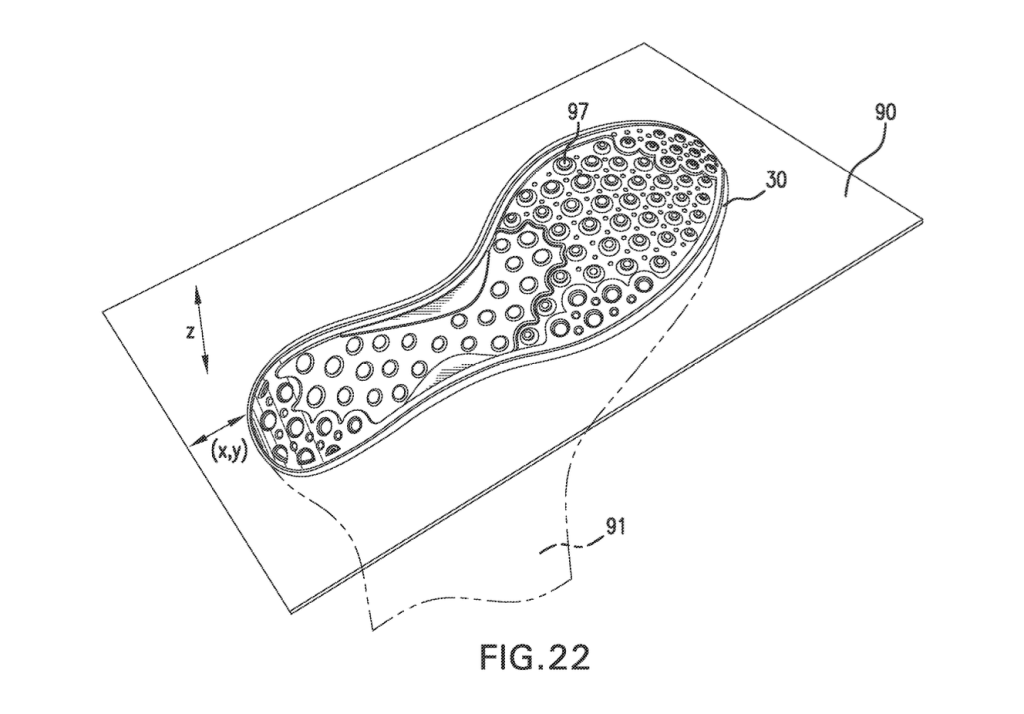

Continuing Nike’s additive manufacturing efforts, the company’s newly patented approach could be used to fabricate 3D printed shoes in the future. According to the official document, digital 3D patterns are first created for the shoe’s upper and sole sections. Next, a piece of knitted, woven, or nonwoven fabric is placed flat on a tray inside a 3D printer. An ink, resin, acrylic, polymer, or thermoplastic-based material is extruded directly onto the fabric to create the desired pattern.

According to the patent, the extruded material may be slightly absorbed into the fabric before curing. Additionally, multiple layers can be 3D printed to create reinforced zones where needed, unlocking added strength and flexibility. Once printed, the pattern is cured with UV light. This step is vital to creating a strong blend between the fabric and extruded material. The flat upper section is then formed into a 3D shape, conforming to the final shoe design.

Next, the upper section is placed upside down inside the 3D printer. Using at least one pre-determined three-dimensional grip pattern, the sole is 3D printed directly onto the upper. The patent highlights that midsole and outsole layers can be made from flexible, cushioned materials like polyurethane or foam rubber, enhancing comfort and durability. Additionally, an optional sock liner can be added to the upper for a more secure fit. The sole section is also UV-cured to harden the material. Finally, the completed shoe undergoes quality control checks.

The patent indicates that this process applies to a variety of sports footwear, including shoes for athletics, basketball, soccer, cycling, tennis, baseball, cross-training, and hiking. It also highlights that the method can be applied to create other types of footwear, such as dress shoes, loafers, sandals, slippers, boat shoes, and work boots.

Additionally, the document reveals that Nike’s new 3D printing process isn’t limited to footwear. It can also be used to manufacture a range of clothing, apparel, and equipment, such as hats, jackets, shirts, gloves, and other sports gear made from fabric, leather, rubber, and foam.

This draws parallels with other technologies in the garment 3D printing space. Israel-based 3D printer manufacturer Stratasys, for instance, offers the J850 TechStyle fashion 3D printer. This system features direct-to-textile technology that can 3D print designs and patterns directly onto clothing such as jeans and jackets. The 3D printer is compatible with denim, cotton, polyester, and linen fabrics, allowing designers and fashion brands to personalize wearable products and meet customer style preferences. According to Stratasys, its fashion printing process minimizes material waste by converting old outfits into new, bespoke fashion products.

3D printed shoes: a growing industry trend

3D printed shoes are a growing trend in the additive manufacturing and footwear industries. Increasing interest is driven by the technology’s ability to create unique and personalized designs to meet customer needs with minimal material usage.

Nike isn’t the only footwear brand to embrace additive manufacturing. Earlier this year, the luxury Italian fashion brand Gucci expanded its Spring Summer 2025 (SS25) collection by introducing several new designs of its 3D printed Cub3d sneakers. Initially released last year in a limited run of just 20 pairs, the sneakers are now available in five color options: Purple, Grey, Black, Brown, and Grey-and-white.

These 3D printed shoes combine Demetra and mesh in their upper construction. Gucci developed the Demetra material, at least 70% of which is composed of vegetable-derived raw ingredients like viscose, wood pulp, and bio-based polyurethane. The bi-material sole features an EVA-filled cushioning interior and a TPU exterior for added flexibility.

Elsewhere, Florida-based footwear developer Syntilay recently introduced new 3D printed sliders designed using artificial intelligence (AI). Available for $150, the shoes are 3D printed to meet specific customer specifications. Buyers scan their feet with a smartphone camera to produce an accurate model for sizing. Human designers sketch the initial concepts before AI platforms like MidJourney refine these ideas into more detailed forms. AI design software Vizcom then converts the sketches into 3D models, which are fabricated in collaboration with Zellerfeld.

Another company 3D printing footwear is ELASTIUM. Last year, the UAE-based startup partnered with LaLaLand Production & Design, California’s largest shoe manufacturer, to expand additive manufacturing in the footwear industry. The companies are working to accelerate localized and sustainable mass production through their No-MMOQ hybrid production model, which can reportedly cut initial investment costs by up to 80%.

The first product launched under this collaboration, the Orca, Elastium’s latest 3D printed sneaker. It combines a TPU foam midsole with an elastane and TPU upper. Shipping for this product commenced last November, with prices starting at $250.