In a world increasingly conscious of environmental footprints, OXMAN has stepped up to the plate with its revolutionary O° platform, introducing footwear that’s not just stylish but also 100% biodegradable. Let’s dive into this groundbreaking innovation that’s set to reshape the future of sustainable fashion.

The Genesis of OXMAN’s O° Platform

Understanding Polyhydroxyalkanoates (PHAs)So, what’s the magic material behind this innovation? Enter PHAs—a class of organic materials produced by bacteria. These biopolymers are not only versatile but also fully biodegradable, breaking down naturally without leaving harmful residues. Unlike traditional plastics that linger for centuries, PHAs return to the earth, making them a game-changer in sustainable manufacturing.

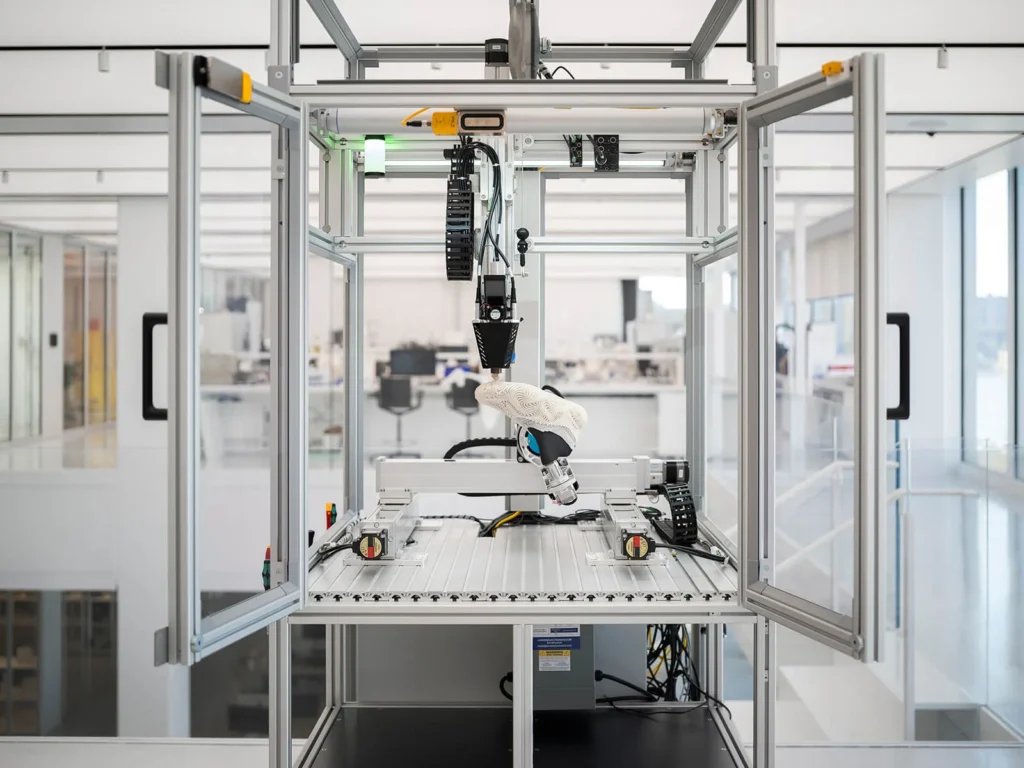

OXMAN didn’t just stop at choosing the right material. They’ve integrated cutting-edge digital, biological, and robotic technologies to craft their footwear. By employing 3D knitting and 3D printing techniques, they’ve eliminated the need for traditional cut-and-sew methods, resulting in a seamless design that’s both efficient and eco-friendly.

The O° shoe isn’t just about sustainability; it’s designed with the wearer in mind. Tailored to complement human motion, each shoe boasts a knitted upper layer for comfort and flexibility, while the outer layers are 3D printed to provide reinforcement and durability. Whether you’re gearing up for a run or a casual stroll, there’s a design suited to your needs.

Environmental Impact and SustainabilityOne of the standout features of the O° shoe is its zero microplastics production upon decomposition. Traditional footwear often contributes to microplastic pollution, but with OXMAN’s design, the shoes naturally break down without leaving a trace. Plus, by streamlining production to minimize waste and reduce transportation emissions, the O° platform sets a new standard in eco-friendly manufacturing.

Bio-Engineered Pigmentation

Color plays a crucial role in fashion, and OXMAN has innovated here too. Instead of relying on petrochemical-based dyes, they’ve harnessed bacteria to produce natural pigments. This approach not only reduces environmental harm but also offers a palette of colors derived straight from nature.

The brilliance of the O° platform lies in its holistic approach. With minimal human intervention, the production process is nearly zero-waste, scalable, and adaptable to various applications beyond footwear. It’s a blueprint for how future manufacturing can be both efficient and environmentally responsible.

While OXMAN’s O° platform represents a significant leap in sustainable footwear design, scaling this innovation presents certain challenges. Transitioning from a pioneering concept to mass production necessitates substantial investment in advanced manufacturing infrastructure and the establishment of a supply chain for polyhydroxyalkanoates (PHAs). Educating consumers about the benefits of biodegradable footwear is also crucial for widespread adoption.

Despite these hurdles, the future appears promising. OXMAN’s commitment to integrating design, technology, and biology positions them to overcome these challenges. Their interdisciplinary approach fosters continuous innovation, paving the way for broader applications of the O° platform beyond footwear, potentially revolutionizing various sectors with sustainable solutions.

Consumer Reception and Market Impact

The introduction of the O° shoe has garnered positive attention from both consumers and industry experts. The footwear design and manufacturing industry faces significant environmental challenges, including hazardous chemical formulations polluting ecosystems and the accumulation of non-biodegradable waste in landfills. OXMAN’s O° shoe addresses these issues by offering a 100% biodegradable alternative, producing zero microplastics. This innovation not only appeals to eco-conscious consumers but also sets a new standard for sustainability in the footwear industry.As the demand for environmentally responsible products continues to rise, OXMAN’s O° platform is well-positioned to make a substantial impact on the market. By leading the charge in sustainable design, OXMAN is not only meeting current consumer expectations but also inspiring other companies to adopt similar practices, potentially transforming the future landscape of consumer goods.

OXMAN is actively seeking collaborations with investors and brands to scale the production of O° shoes and textiles. By partnering with like-minded entities, they aim to bring these sustainable products to a broader market, making eco-friendly footwear more accessible to consumers worldwide.

Beyond product development, OXMAN’s O° platform serves as an educational tool, raising awareness about the potential of biodegradable materials in consumer products. Their innovative approach influences design and engineering education, inspiring a new generation to prioritize sustainability in their creations.

Comparative Analysis with Other Sustainable Footwear

While several brands have ventured into sustainable footwear, OXMAN’s O° shoe distinguishes itself by being made entirely from PHAs, ensuring complete biodegradability without leaving microplastics behind. This mono-material approach simplifies recycling and sets a new benchmark in eco-friendly design.

The O° platform’s potential extends beyond footwear. With its versatile design and manufacturing capabilities, there’s a promising future for expanding into other wearable products, such as apparel and accessories, all adhering to the same principles of sustainability and biodegradability.

Conclusion

OXMAN’s O° platform represents a significant leap forward in sustainable design, offering a harmonious blend of innovation, functionality, and environmental responsibility. As consumers, supporting such initiatives not only brings us closer to nature but also paves the way for a greener future in fashion and beyond.

FAQs

- What makes the O° shoe different from other eco-friendly footwear? The O° shoe is made entirely from polyhydroxyalkanoates (PHAs), ensuring it’s 100% biodegradable without leaving any microplastics behind. This mono-material approach sets it apart from other sustainable footwear options.

- How long does it take for the O° shoe to decompose? While specific decomposition times can vary based on environmental conditions, PHAs are known to biodegrade efficiently in natural settings, returning to their bacterial origins without harming the environment.

- Are the O° shoes durable for everyday use? Yes, the O° shoes are designed with both durability and comfort in mind, suitable for various activities, including running and walking. They maintain integrity during wear, washing, and storage.

- Will the O° platform expand to other products besides footwear? OXMAN envisions applying the O° platform to a range of wearable products, including textiles and accessories, all adhering to the same sustainable and biodegradable principles.

- How can consumers support OXMAN’s sustainable initiatives? Consumers can support by choosing OXMAN’s products, spreading awareness about sustainable fashion, and encouraging brands to adopt eco-friendly practices in their production processes.